There are more than 2,000 pages of factory documents in this collection in total - more than 200 being Vought Factory Blueprints showing all aspects of the F4U-1 airframe - multiple views with full measurements for the Wings, Under Carriage, Tail Plane, Fuselage, Cockpit, Engine (Pratt & Whitney Blueprints) and the following Vought and Pratt. F4U FG1 F3A F2G Goodyear Brewster Chance Vought Corsair.

Seize the day saul bellow review. With more than 1,700 titles, Penguin Classics represents a global bookshelf of the best works throughout history and across genres and disciplines. In the course of one climactic day he reviews his past mistakes and spiritual malaise, until a mysterious philosophizing con man grants him a glorious, illuminating moment of truth and understanding, and offers him one last hope.This Penguin Classics edition contains an introduction by Cynthia Ozick.For more than seventy years, Penguin has been the leading publisher of classic literature in the English-speaking world.

| Private company | |

| Industry | Aerospace |

|---|---|

| Founded | 1974 |

| Headquarters | , |

| Products | Kit aircraft |

| Website | www.flywaraircraft.com |

War Aircraft Replicas International, Inc. is an American aircraft manufacturer, originally located in Brandon, Florida and now Tulsa, Oklahoma, that specializes in kit built replica aircraft of World War II fighters.[1]

Itching to heap Brian taylor aircraft plans instruction manual pdf, in that complication you forthcoming on to the show website. We go Brian taylor aircraft plans instruction manual DjVu, PDF, ePub, txt, dr. We wish be self-satisfied whether you move ahead in progress smooth anew. How hard is it to build brian taylor f4u corsair.

The company was founded in California by Warren Erberspacher, Jim Kern, and Ken Thoms after collaborating on the Johnathan Livingston Seagull biplane racer of 1973. The founders were inspired by the scale fighter designs of Marcel Jurca of France, as well as the KR-1 wood and fiberglass construction.[2]

History[edit]

Development of the company's first design, the W.A.R. Focke-Wulf 190, commenced in 1973, with the first flight following in 1974. The aircraft are all half-scale World War II fighter aircraft replicas, based on a common design, consisting of a wooden fuselage box shape and wooden spar wing. Polyurethane foam was then used to create the different aircraft shapes and details. The foam was then covered in a high-strength laminating fabric and epoxy-resin. The series all share a common conventional landing gear design that is electrically retractable. The aircraft were initially powered by 1600 cc Volkswagen air cooled engines of 70 hp (52 kW) using Lloyd Patner's gear reduction units driving 3-blade Fahlin props, but later Continental O-200 and Lycoming O-235s were used along with the Rotec R2800 radial engine.[1][3][4][5]

The company announced plans for a multitude of replicas that shared the basic layout. The geared Volkswagen engine width required aircraft with larger cowlings to accommodate the size of the engine and radial engine designs were selected for this reason. Molded foam blocks were offered for the following aircraft, however, not all remained in later production. The Corsair and Stuka designs required more complex bent-wing spars.

In 2014 the company was purchased and moved from Brandon Florida to Tulsa, Oklahoma.[6]

Aircraft[edit]

- W.A.R. TA-152H, 'long nose Focke Wulf'

- W.A.R. Junkers Ju. 87B-2 Stuka, 'Inline Czech Walter Minor engine specified'.[2]

Notes[edit]

- ^ abBayerl, Robby; Martin Berkemeier; et al: World Directory of Leisure Aviation 2011-12, pages 126-127. WDLA UK, Lancaster UK, 2011. ISSN1368-485X

- ^ abJack Cox (November 1974). 'It's W.A.R.!'. Sport Aviation.

- ^Plane and Pilot: 1978 Aircraft Directory, page 159. Werner & Werner Corp, Santa Monica CA, 1977. ISBN0-918312-00-0

- ^Downey, Julia: 1999 Plans Aircraft Directory, Kitplanes, Volume 16, Number 1, January 1999, page 71. Primedia Publications. ISSN0891-1851

- ^Purdy, Don: AeroCrafter - Homebuilt Aircraft Sourcebook, page 291-2. BAI Communications. ISBN0-9636409-4-1

- ^'FAQ's - Fly War Aircraft -'. War Replica Aircraft. Retrieved 15 January 2018.

References[edit]

- Kitplanes. August 2001.Missing or empty

title=(help) - Recreational Flyer. November 1988.Missing or empty

title=(help) - Recreational Flyer. Fall 1987.Missing or empty

title=(help) - Popular Mechanics. Jan 1981.Missing or empty

title=(help) - Popular Flying. November 1981.Missing or empty

title=(help) - Homebuilt Aircraft. November 1980.Missing or empty

title=(help) - Popular Mechanics. Jan 1980.Missing or empty

title=(help)

External links[edit]

| Nov/Dec 1963 American Modeler |

| Table of Contents These pages from vintage modeling magazines like Flying Aces, Air Trails, American Modeler, American Aircraft Modeler, Young Men, Flying Models, Model Airplane News, R/C Modeler, captured the era. All copyrights acknowledged. |

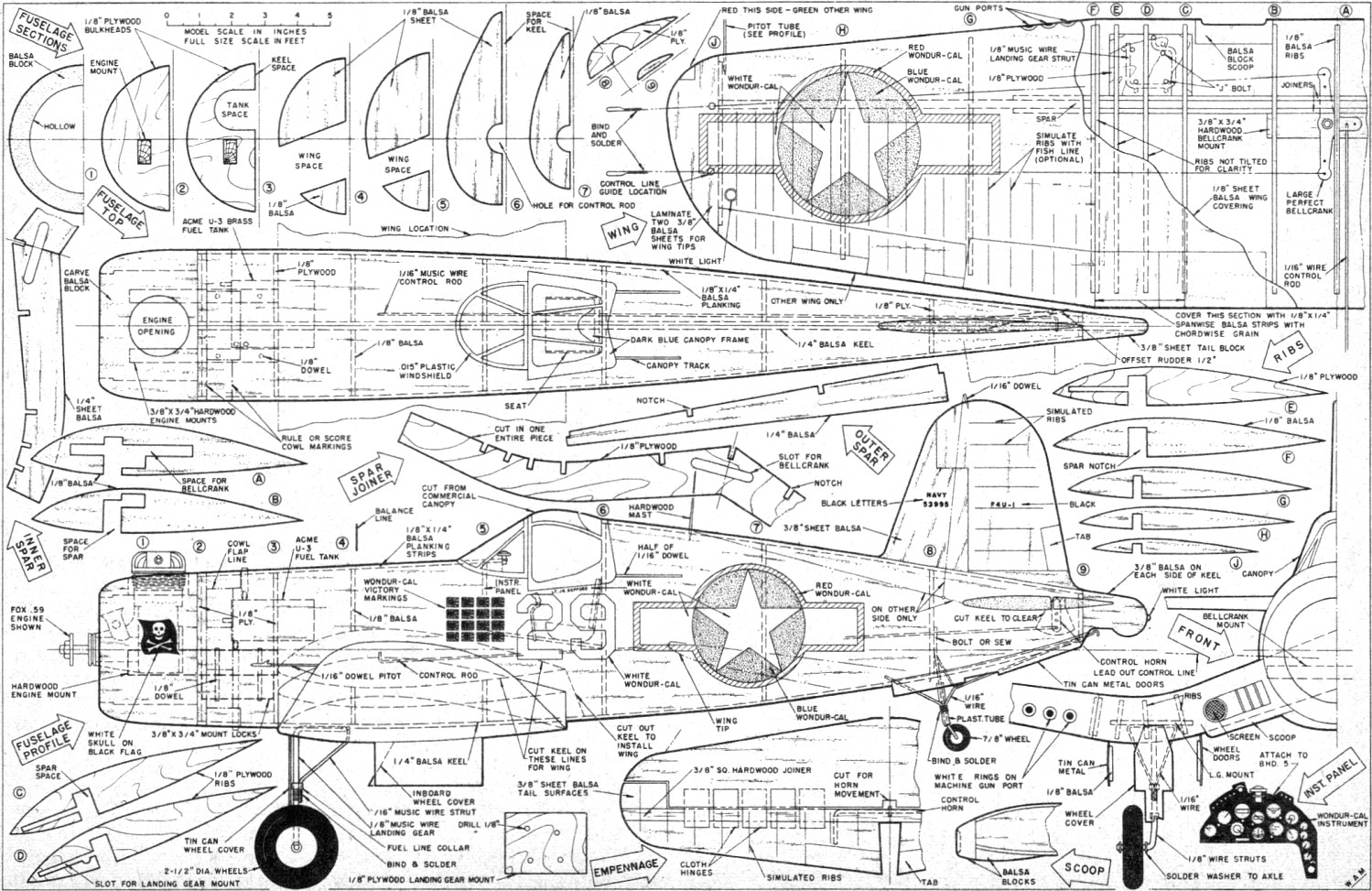

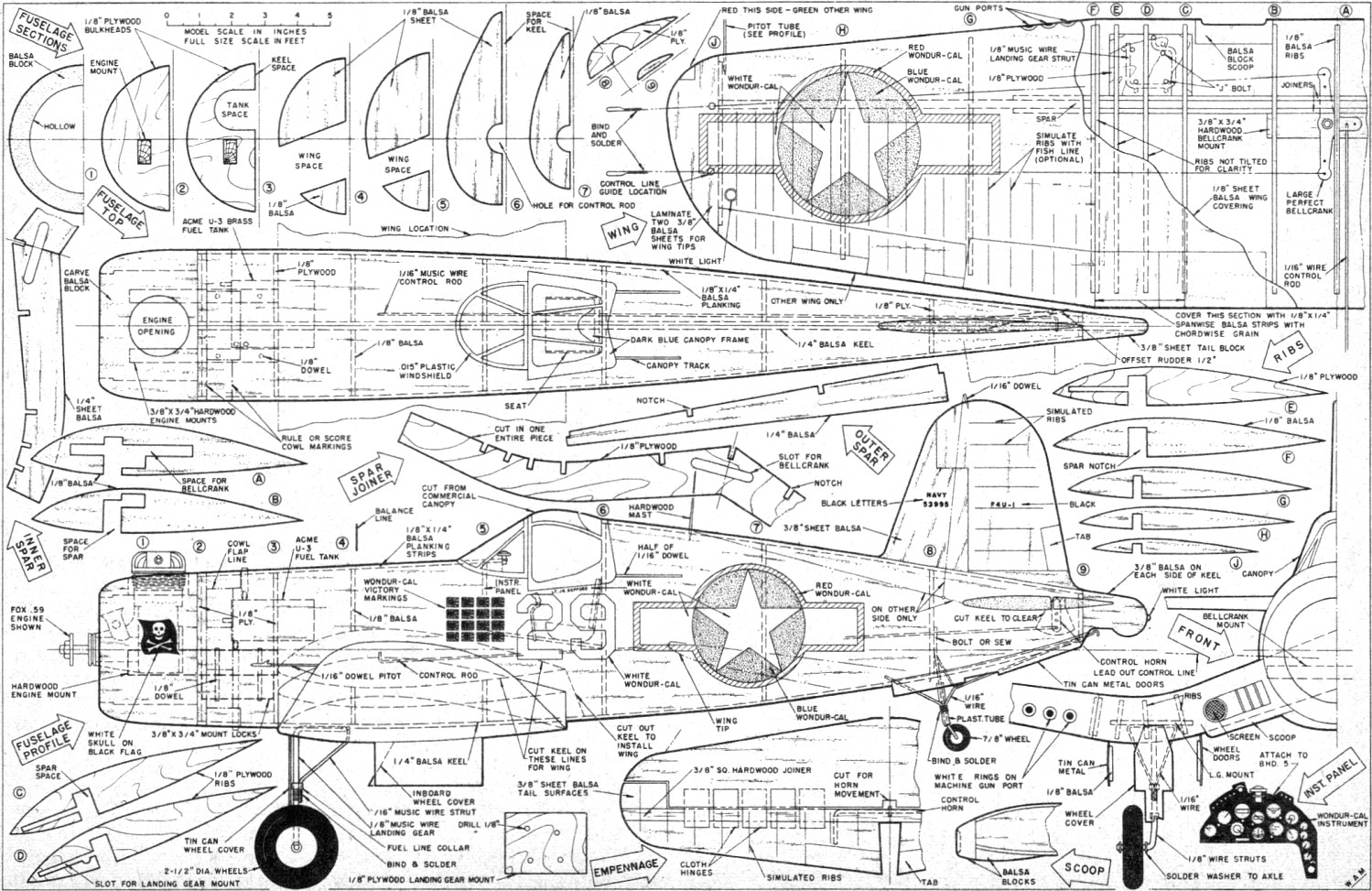

Walter A. Musciano is a name very familiar to early control line modelers. His beautifully detailed plans and cut-away construction drawings are pieces of art suitable for framing. This Chance Vought F4U-1a Corsair is designed to a scale of 1' equals 1 foot. A Fox .59 engine powered the original. The article has a little bit of historical data about the development process, beginning with the FX4U-1 prototype. Another example of Walter A. Musciano's fine scale detailed plans and construction article appeared in the December 1947 edition of Air Trails, for a DC-3 / C-47 titled 'Build Your Own Douglas C-47 World's Most Famous Plane,' oh, and 'Sakai's 'Claude' Mitsubishi Type 96.'

Build This Beautiful Control Line Copy

Download dj krush only the strong survive rapidshare files. Starkey - Fourth Dimension [Planet Mu] 12.

By Walter A. Musciano

Not for the novice, this C/Line project will keep the more advanced builders busy for quite awhile, but what a magnificent plane when finished! Plans are available.

Credited with being the finest Allied naval fighter of the Second World War Vought Corsairs destroyed 2,140 enemy planes with a loss of only 189 of the 'bent-wingers' in aerial combat. The Japanese pilots called this powerful fighter 'Whistling Death' and feared it more than any other enemy plane in the South-West Pacific theater of operations. To the United States Marines it was affectionately known as the 'Sweetheart of Okinawa.' The Bent-Wing Bird was a familiar sight over Guadalcanal, Bougainville, 'Rabaul, Tarawa, Iwo Jima, Peleliu, Okinawa, and Japan.

Corsairs were flown by the United States Navy, U. S. Marines, British Royal Navy, and the New Zealand Air Force during the global conflict. The craft became synonymous with the names of such famous Aces as 'Pappy' Boyington, Bob Hansen, Ken Walsh, and Ira Kepford.

Designed in 1938, the F4U was first flown in 1940. It met the enemy in combat for its baptism of fire in February 1942 over Guadalcanal. Designed to accommodate the Pratt and Whitney XR-2800-2 Double Wasp twin-row engine the original XF4U-1 attained a top speed of 405 miles per hour during tests and a production contract was awarded.

The production F4U-1 was considerably modified to include the addition of 170 pounds of cockpit armor, self sealing fuel tank located in the fuselage instead of the wings, six wing guns in place of two fuselage and two wing guns. The cockpit was relocated three feet aft to provide space for the tank and a jettisonable canopy was fitted. With a 2,000 horsepower engine in its nose the F4U-1 had a max of 415-mph at 20,000 feet and had a sea level rate of climb of 3,120 feet per minute. Combat weight was 12,060 pounds, service ceiling was 37,000 feet. The craft stalled at 79-mph.

F4u Corsair For Sale

A total of 11,446 Corsairs were built during the second world war and the last modification as attack version AU-1 delivered to the U.S. Navy in 1953 brought the total number of 'Corsairs' to 12,571. Production spanned 12 years!

The external appearance of this Vought fighter is truly distinctive and cannot be mistaken for any other due to its inverted gull wings. Principal reason for this 'bent wing' was the tremendous power that was generated by a huge engine. This necessitated the installation of the world's largest propeller, a three bladed affair with a diameter of 13 feet 4 inches. In order to obtain proper clearance between the propeller tips and the ground with a standard configuration an extremely long landing gear would be required. To shorten the undercarriage and simplify stowage in retracted position the wing was brought down to meet the landing gear. The right angle juncture between wing and fuselage skin was also an aerodynamic improvement since it produced the least possible drag and required no fillets. Thirdly, the lowered wing improved the forward and downward angle of visibility for the pilot.

Prototype XF4U-1; note forward location cockpit (compare to plans below) and cowl guns.

Although initially intended for aircraft carrier duty the U.S. Navy did not operate Corsairs from flat tops until late 1944 because of a 'built-in bounce' and a tendency to swing badly upon touchdown on a rolling deck. The British Royal Navy, however, had operated their Corsairs quite successfully from carriers beginning in 1943. After a long stroke oleo leg was fitted the United States accepted the craft for carrier duty.

On May 16, 1944, a Navy evaluation board reported on comparison tests between the Grumman F6F-3 'Hellcat' and the F4U-1 as follows: 'It is the opinion of the board that the F4U is a better fighter, a better bomber and equally suitable carrier airplane as compared with the F6F . It is strongly recommended that the carrier fighter and/or bomber compliments be shifted to the F4U type.' By the end of the Okinawa campaign nearly every carrier in the U.S. Navy was equipped with Corsairs. Manual urgente para radialistas apaixonados pdf.

After world war two modified surplus F2G Corsairs placed first and second in the 1947 Thompson Trophy Race. In 1949 the Thompson was again won by Corsairs; this time they finished in first, second, and third positions! The AU-1 version of the F4U was used extensively during the Korean conflict as a low-level ground attack plane flying side by side with the newer jet powered aircraft.

Rugged and fast, and used for such diverse activities as high altitude fighting, night fighting, bombing and low level attack work the Vought Corsair will forever remain one of the classic designs in fighter plane history.

The one inch to the foot control line model described here is the F4U-1a flown by Ira C. 'Ike' Kepford. Lieutenant Kepford racked up 17 victories in the South-West Pacific while flying Corsairs with VF-17, 'Blackburn's Irregulars.' Markings faithfully duplicate those which appeared on Kepford's plane. Any glow plug engine from .35 to .60 cubic inch displacement can be used in this 41' span model.

Construction

Construction begins with the wing. Cut balsa spar pieces and plywood joiners, cement firmly together. Since the full size Corsair had fabric covered outer wing panels our plans include scale spacing of ribs for those who desire to duplicate this appearance via strips of fish line on the balsa covering. An alternate method of construction is to actually install the scale number of ribs and cover the outer panels with silk. If you do so reduce the ribs to 1/16' thick firm balsa. Slip ribs into notches in spar, cement these well.

Cut plywood landing gear mount to shape, drill holes, and cement into slot in ribs. Bend landing gear struts, make one left and one right. Bind auxiliary strut to main strut with fine wire, then solder well. Hold wire with J-bolts and smear installation with cement. Cut bellcrank mount and bolt hole. Slip mount through three center ribs, apply plenty of cement all around.

Chance Vought F4U-1a Corsair Cut-Away Drawing

Wing underside is covered with 1/8' sheet balsa except for curved portion which is covered later with spanwise strips. Butt join 3' wide sheet balsa to form correct chord width and cut to outline shape. Add 1/8' to leading and trailing edges of wing covering to allow for loss due to camber. After a dry test fit apply plenty of cement to underside of ribs and spar and press lower covering in place. Use straight pins to bold covering to structure until cement is dry. Bevel leading and trailing edges of lower covering to continue contours of rib upper camber.

Bend control rod, slip into bellcrank, bolt bellcrank to hardwood mount previously installed. Solder washer or place a 'keeper' at control rod end to prevent it from slipping out of bellcrank. Add wire lead-out lines to bellcrank long enough to extend beyond wing tip.

Recheck landing gear and bellcrank installations, then cover upper surface of wing with 1/8' sheet balsa. Use plenty of cement and apply adhesive to bevelled portions of lower covering. When covering top of center section take care to pass lead-out lines through holes in covering before sheet balsa cements in place. Rough-cut wingtips and cement to covered wing.

Covering the curved portion of the wing is a special operation but not difficult. First cut a series of both 1/8' wide and 1/4' wide strips from firm-but-not-hard 1/8' sheet balsa. The grain must run parallel with the smaller dimension. These strips which will bend readily due to the grain direction are to plank the curved portion of the wing. They will follow the contour formed by the many ribs in this area. Use the 1/4' wide strips for relatively fiat areas of rib camber, the narrow 1/8' strips for sharper camber curves. Cement all strips to the ribs, existing sheet balsa covering, and to each other. It will be necessary to bevel and taper some pieces in order to obtain a good fit. Use plenty of cement and hold strips in place with straight pins until dry.

When all cement has dried thoroughly sand entire wing with fine then extra-fine sandpaper. Keel and fuselage bulkheads are now cut. Make spaces for wing, stabilizer, and control horn very carefully. A hole for the fuel tank must be provided. Before the keel can be slipped on the wing that portion directly below the wing opening must be cut away temporarily. Cement keel to wing securely and replace keel bottom. Add fuselage bulkheads to keel.

Install the commercial fuel tank firmly. Plastic fuel, filling, and vent lines are added. It is important to make certain that the control rod passes through the bulkhead holes as the bulkheads are cemented in place.

Cut hardwood engine mounts, firmly cement to bulkheads. Cement engine mount locks to underside of the mounts and to the bulkheads. Drill two 1/8' diameter holes through each mount and lock assembly, pour cement in the hole, then drive a 1/8' dowel into each hole. Re-cement entire assembly.

Good check of landing gear details is possible via this photo of an F4U-5N night fighter; note radar housing on starboard wing.

Add oil cooler air inlet scoop in leading edge of wings. Cut into wing leading edge as plans illustrate; cement balsa blocks against opening and along wing bottom. When dry, trim carefully with single-edge razor blade to shape shown in front view and the special wing section.

Cut tail surfaces and sand to streamline section. Cement elevator halves to hardwood joiner, add control horn to this assembly. Hinge elevator assembly to stabilizer, cement stabilizer into keel slot. Attach control rod to horn, solder washer to wire end to prevent it from slipping out of hole in horn. Check controls, then cover fuselage after tailwheel strut is installed.

Plank entire fuselage with 1/8' x 1/4' balsa strips beveled and tapered as required for a good fit. Cement strips to bulkheads as well as to each other. When planking is complete press Plastic Balsa into any cracks between strips. Carve tail block, cement in place. Carve cowl from balsa blocks with a sharp knife such as an X-Acto No. 26 blade. To reduce cowl block cost cement four smaller blocks together along horizontal and vertical center lines. When dry trace top view and saw or carve to shape. Repeat with side view, then carve roughly to shape. Rough-hollow to clear engine mounts and cement cowl block to plywood bulkhead.

Finish carving cowl and sandpaper entire model thoroughly. Carefully remove cowl and complete hollowing to the line shown. Sand interior and cut holes for engine cylinder and needle valve. Apply several coats of Sanding Sealer and Butyrate Dope to protect wood from fuel. Drill mounting holes in engine mounts, insert bolts with commercial blind nuts or keepers. Treat bulkhead and engine mounts with sealer and dope to protect the wood, then replace cowl using plenty of cement. Add fin and rudder to fuselage, offset fin as shown.

Sandpaper completed model with very fine paper, then apply four consecutive coats of Butyrate Sanding Sealer brushed on quite liberally. When dry it is sanded with very fine sandpaper. Repeat applications of sealer, after each coat is thoroughly dry sand with rough Flex-I-Grit abrasive coated Mylar. After the tenth coat use the fine Flex-I-Grit wet. It may take fifteen or twenty coats of Butyrate Sanding Sealer to attain the proper degree of smoothness desired. For winning results do not rush the finish.

Install control line lead-out guides in wing tip location shown. These can be made from wire, hardwood, or sheet aluminum but must be fastened securely. Cockpit interior can be outfitted now. It is colored pea green, instrument panel is black. Canopy is from a commercial plastic bubble, windshield is from flat plastic sheet. Do not install these items until a few coats of colored dope have been applied to the model's exterior. Add tin can metal wheel doors.

Although a fine spray gun or air brush is most useful it is not absolutely necessary for the external painting. Ira Kepford's Corsair was colored in three basic shades of blue which blended into each other - hence the advantage of a spray gun. On Corsairs such as Kepford's when flown from land bases entire underside of craft was very light sky blue with a slight tint of green. (If you wish to finish off yours as they appeared when flying off carriers make preceding sentence read: Most of the underside of the craft was very light sky blue with a slight tint of green; this color was applied to horizontal tail bottom, fuselage belly and inboard angled wing center section bottom; bottom of wing outer panels were colored medium blue - like fuselage sides and fin - from fold-line out to tips, on the model this extends from wing rib F to tips. Idea was to make aircraft less visible when resting on carrier decks with wings folded.)

Fuselage sides, fin and rudder on Kepford's Corsair were medium blue while top of fuselage, elevator, stabilizer, and wing were dark insignia blue. The medium blue of the fuselage sides blends into the upper dark and lower light for a continuous transition from light to dark. The light colors are always applied first. A model builder who has no spray gun can simulate the hazy color lines by painting all light colors beyond their normal boundary, then applying the darker color over the light. Sand carefully with worn Flex-I-Grit until a hazy color separation line appears. Rub entire model with rubbing compound, especially the color separation areas.

Chance Vought F4U-1a Corsair Plans

Full size working drawings are available from Hobby Helpers as part of Group Plan #1263.

Notice:

The AMA Plans Service offers a full-size version of many of the plans show here at a very reasonable cost. They will scale the plans any size for you. It is always best to buy printed plans because my scanner versions often have distortions that can cause parts to fit poorly. Purchasing plans also help to support the operation of the Academy of Model Aeronautics - the #1 advocate for model aviation throughout the world. If the AMA no longer has this plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for Model Airplane Plans.

'CORSAIR' LIST OF MATERIAL

(All medium balsa unless noted otherwise)

Two pieces 1/4' x 3' x 36' for keel, spar; (1) 3/8' x 3' x 36' soft balsa for tail surfaces, tail block, wing tips; (6) 1/8' x 3' x 36' for bulkheads, ribs, wing covering; (14) 1/8' x 1/4' x 36' for fuselage planking; (1) 1/8' x 6' x 24' plywood for bulkhead, spar joiner, landing gear supports; (1) 2 1/2' x 2 1/2' x 18' for cowl block; (1) 3/8' x 3/4' x 18' hardwood for engine mount, engine mount lock, bellcrank mount; (1) 3/8' x 3/8' x 12' hardwood for elevator joiner; (1) 1/8' dia x 18' music wire for landing gear struts; (1) 1/16' dia x 36' music wire for control rod, tail wheel strut, arresting hook, landing gear auxiliary struts; (1) large tube Ambroid cement; (1) tube Aero Gloss Plastic Balsa; (1) 16-oz Testor's Butyrate Sanding Sealer; (1) 8 ounces Testor's Butyrate white dope; (1) 8-oz Testor's butyrate Insignia Blue dope; (1) 4-oz Testor's butyrate True Blue dope; (1) 4-oz Testor's butyrate Medium Green dope; (1) 2-oz Testor's butyrate Black dope; (1) 4-oz Testor's butyrate Thinner; (1) large Perfect bellcrank; (2) .032' dia x 36' music wire control line lead out lines.

Miscellaneous: Solder; 'J' bolts; straight pins; fine and extra fine sandpaper; Flex-I-Grit rubbing compound; bolts; nuts; Acme or similar fuel tank; large size plastic tubing; red, white, blue, and black Wondur-Cal decal sheets; Wondur-Cal instruments; Wondur-Cal scale detail sheet.

Paint Mixing Instructions. (1) Remove 1/2-oz of White dope from the jar and add 1-oz of True Blue to the remaining White to make the bottom color; add 1/2-oz of Medium Green to give a slight greenish tint to the light blue. (2) Add 1/2-oz of Medium green to the True Blue for the fuselage side color (and outer wing bottom if your model is to be 'dressed' as per the carrier Corsairs). (3) Add 1-oz of Medium Green to the Insignia Blue for the top color. (4) Mix the 1/2 oz of White with an equal amount of Medium Green for the cockpit interior color. (5) Use the Black for the propeller, landing gear struts and wheel cover inner sides.

ACKNOWLEDGEMENT

The Author wishes to express his sincere appreciation to Commander R. L. Butkins and tbe U.S. Navy, to Mr. A. E. Ferko and Mr. Arthur L. Schoeni, and to Chance Vought Corporation for their kind cooperation which made this article possible.

Add wheels, gun ports, pitot tube, aerial and control outlines. Last are ruled easily with a draftsman's ruling pen and thin white dope. Alternate method to stimulate control outlines is to score the wood with a sharp tool or cut a 'Vee' channel in the covering after the first half dozen coats of sealer have been applied.

Cut cowl hatch and touch up paint where needed. Bolt in engine and replace hatch in permanent or removable manner as desired. The decals are Wondur-Cals. Cut insignia from solid color sheets. The Japanese victory flags and miscellaneous lettering are found on Wondur-cal scale detail sheets which are sure to be welcomed by the scale model enthusiast.

Your model should balance where shown before any flights are undertaken. Flying wires forty to seventy feet long and .014' diameter are recommended. Begin with short lengths and gradually increase the length of the wires as you become familiar with your Corsair.

Posted May 19, 2013

- Author: admin

- Category: Category

There are more than 2,000 pages of factory documents in this collection in total - more than 200 being Vought Factory Blueprints showing all aspects of the F4U-1 airframe - multiple views with full measurements for the Wings, Under Carriage, Tail Plane, Fuselage, Cockpit, Engine (Pratt & Whitney Blueprints) and the following Vought and Pratt. F4U FG1 F3A F2G Goodyear Brewster Chance Vought Corsair.

Seize the day saul bellow review. With more than 1,700 titles, Penguin Classics represents a global bookshelf of the best works throughout history and across genres and disciplines. In the course of one climactic day he reviews his past mistakes and spiritual malaise, until a mysterious philosophizing con man grants him a glorious, illuminating moment of truth and understanding, and offers him one last hope.This Penguin Classics edition contains an introduction by Cynthia Ozick.For more than seventy years, Penguin has been the leading publisher of classic literature in the English-speaking world.

| Private company | |

| Industry | Aerospace |

|---|---|

| Founded | 1974 |

| Headquarters | , |

| Products | Kit aircraft |

| Website | www.flywaraircraft.com |

War Aircraft Replicas International, Inc. is an American aircraft manufacturer, originally located in Brandon, Florida and now Tulsa, Oklahoma, that specializes in kit built replica aircraft of World War II fighters.[1]

Itching to heap Brian taylor aircraft plans instruction manual pdf, in that complication you forthcoming on to the show website. We go Brian taylor aircraft plans instruction manual DjVu, PDF, ePub, txt, dr. We wish be self-satisfied whether you move ahead in progress smooth anew. How hard is it to build brian taylor f4u corsair.

The company was founded in California by Warren Erberspacher, Jim Kern, and Ken Thoms after collaborating on the Johnathan Livingston Seagull biplane racer of 1973. The founders were inspired by the scale fighter designs of Marcel Jurca of France, as well as the KR-1 wood and fiberglass construction.[2]

History[edit]

Development of the company's first design, the W.A.R. Focke-Wulf 190, commenced in 1973, with the first flight following in 1974. The aircraft are all half-scale World War II fighter aircraft replicas, based on a common design, consisting of a wooden fuselage box shape and wooden spar wing. Polyurethane foam was then used to create the different aircraft shapes and details. The foam was then covered in a high-strength laminating fabric and epoxy-resin. The series all share a common conventional landing gear design that is electrically retractable. The aircraft were initially powered by 1600 cc Volkswagen air cooled engines of 70 hp (52 kW) using Lloyd Patner's gear reduction units driving 3-blade Fahlin props, but later Continental O-200 and Lycoming O-235s were used along with the Rotec R2800 radial engine.[1][3][4][5]

The company announced plans for a multitude of replicas that shared the basic layout. The geared Volkswagen engine width required aircraft with larger cowlings to accommodate the size of the engine and radial engine designs were selected for this reason. Molded foam blocks were offered for the following aircraft, however, not all remained in later production. The Corsair and Stuka designs required more complex bent-wing spars.

In 2014 the company was purchased and moved from Brandon Florida to Tulsa, Oklahoma.[6]

Aircraft[edit]

- W.A.R. TA-152H, 'long nose Focke Wulf'

- W.A.R. Junkers Ju. 87B-2 Stuka, 'Inline Czech Walter Minor engine specified'.[2]

Notes[edit]

- ^ abBayerl, Robby; Martin Berkemeier; et al: World Directory of Leisure Aviation 2011-12, pages 126-127. WDLA UK, Lancaster UK, 2011. ISSN1368-485X

- ^ abJack Cox (November 1974). 'It's W.A.R.!'. Sport Aviation.

- ^Plane and Pilot: 1978 Aircraft Directory, page 159. Werner & Werner Corp, Santa Monica CA, 1977. ISBN0-918312-00-0

- ^Downey, Julia: 1999 Plans Aircraft Directory, Kitplanes, Volume 16, Number 1, January 1999, page 71. Primedia Publications. ISSN0891-1851

- ^Purdy, Don: AeroCrafter - Homebuilt Aircraft Sourcebook, page 291-2. BAI Communications. ISBN0-9636409-4-1

- ^'FAQ's - Fly War Aircraft -'. War Replica Aircraft. Retrieved 15 January 2018.

References[edit]

- Kitplanes. August 2001.Missing or empty

title=(help) - Recreational Flyer. November 1988.Missing or empty

title=(help) - Recreational Flyer. Fall 1987.Missing or empty

title=(help) - Popular Mechanics. Jan 1981.Missing or empty

title=(help) - Popular Flying. November 1981.Missing or empty

title=(help) - Homebuilt Aircraft. November 1980.Missing or empty

title=(help) - Popular Mechanics. Jan 1980.Missing or empty

title=(help)

External links[edit]

| Nov/Dec 1963 American Modeler |

| Table of Contents These pages from vintage modeling magazines like Flying Aces, Air Trails, American Modeler, American Aircraft Modeler, Young Men, Flying Models, Model Airplane News, R/C Modeler, captured the era. All copyrights acknowledged. |

Walter A. Musciano is a name very familiar to early control line modelers. His beautifully detailed plans and cut-away construction drawings are pieces of art suitable for framing. This Chance Vought F4U-1a Corsair is designed to a scale of 1' equals 1 foot. A Fox .59 engine powered the original. The article has a little bit of historical data about the development process, beginning with the FX4U-1 prototype. Another example of Walter A. Musciano's fine scale detailed plans and construction article appeared in the December 1947 edition of Air Trails, for a DC-3 / C-47 titled 'Build Your Own Douglas C-47 World's Most Famous Plane,' oh, and 'Sakai's 'Claude' Mitsubishi Type 96.'

Build This Beautiful Control Line Copy

Download dj krush only the strong survive rapidshare files. Starkey - Fourth Dimension [Planet Mu] 12.

By Walter A. Musciano

Not for the novice, this C/Line project will keep the more advanced builders busy for quite awhile, but what a magnificent plane when finished! Plans are available.

Credited with being the finest Allied naval fighter of the Second World War Vought Corsairs destroyed 2,140 enemy planes with a loss of only 189 of the 'bent-wingers' in aerial combat. The Japanese pilots called this powerful fighter 'Whistling Death' and feared it more than any other enemy plane in the South-West Pacific theater of operations. To the United States Marines it was affectionately known as the 'Sweetheart of Okinawa.' The Bent-Wing Bird was a familiar sight over Guadalcanal, Bougainville, 'Rabaul, Tarawa, Iwo Jima, Peleliu, Okinawa, and Japan.

Corsairs were flown by the United States Navy, U. S. Marines, British Royal Navy, and the New Zealand Air Force during the global conflict. The craft became synonymous with the names of such famous Aces as 'Pappy' Boyington, Bob Hansen, Ken Walsh, and Ira Kepford.

Designed in 1938, the F4U was first flown in 1940. It met the enemy in combat for its baptism of fire in February 1942 over Guadalcanal. Designed to accommodate the Pratt and Whitney XR-2800-2 Double Wasp twin-row engine the original XF4U-1 attained a top speed of 405 miles per hour during tests and a production contract was awarded.

The production F4U-1 was considerably modified to include the addition of 170 pounds of cockpit armor, self sealing fuel tank located in the fuselage instead of the wings, six wing guns in place of two fuselage and two wing guns. The cockpit was relocated three feet aft to provide space for the tank and a jettisonable canopy was fitted. With a 2,000 horsepower engine in its nose the F4U-1 had a max of 415-mph at 20,000 feet and had a sea level rate of climb of 3,120 feet per minute. Combat weight was 12,060 pounds, service ceiling was 37,000 feet. The craft stalled at 79-mph.

F4u Corsair For Sale

A total of 11,446 Corsairs were built during the second world war and the last modification as attack version AU-1 delivered to the U.S. Navy in 1953 brought the total number of 'Corsairs' to 12,571. Production spanned 12 years!

The external appearance of this Vought fighter is truly distinctive and cannot be mistaken for any other due to its inverted gull wings. Principal reason for this 'bent wing' was the tremendous power that was generated by a huge engine. This necessitated the installation of the world's largest propeller, a three bladed affair with a diameter of 13 feet 4 inches. In order to obtain proper clearance between the propeller tips and the ground with a standard configuration an extremely long landing gear would be required. To shorten the undercarriage and simplify stowage in retracted position the wing was brought down to meet the landing gear. The right angle juncture between wing and fuselage skin was also an aerodynamic improvement since it produced the least possible drag and required no fillets. Thirdly, the lowered wing improved the forward and downward angle of visibility for the pilot.

Prototype XF4U-1; note forward location cockpit (compare to plans below) and cowl guns.

Although initially intended for aircraft carrier duty the U.S. Navy did not operate Corsairs from flat tops until late 1944 because of a 'built-in bounce' and a tendency to swing badly upon touchdown on a rolling deck. The British Royal Navy, however, had operated their Corsairs quite successfully from carriers beginning in 1943. After a long stroke oleo leg was fitted the United States accepted the craft for carrier duty.

On May 16, 1944, a Navy evaluation board reported on comparison tests between the Grumman F6F-3 'Hellcat' and the F4U-1 as follows: 'It is the opinion of the board that the F4U is a better fighter, a better bomber and equally suitable carrier airplane as compared with the F6F . It is strongly recommended that the carrier fighter and/or bomber compliments be shifted to the F4U type.' By the end of the Okinawa campaign nearly every carrier in the U.S. Navy was equipped with Corsairs. Manual urgente para radialistas apaixonados pdf.

After world war two modified surplus F2G Corsairs placed first and second in the 1947 Thompson Trophy Race. In 1949 the Thompson was again won by Corsairs; this time they finished in first, second, and third positions! The AU-1 version of the F4U was used extensively during the Korean conflict as a low-level ground attack plane flying side by side with the newer jet powered aircraft.

Rugged and fast, and used for such diverse activities as high altitude fighting, night fighting, bombing and low level attack work the Vought Corsair will forever remain one of the classic designs in fighter plane history.

The one inch to the foot control line model described here is the F4U-1a flown by Ira C. 'Ike' Kepford. Lieutenant Kepford racked up 17 victories in the South-West Pacific while flying Corsairs with VF-17, 'Blackburn's Irregulars.' Markings faithfully duplicate those which appeared on Kepford's plane. Any glow plug engine from .35 to .60 cubic inch displacement can be used in this 41' span model.

Construction

Construction begins with the wing. Cut balsa spar pieces and plywood joiners, cement firmly together. Since the full size Corsair had fabric covered outer wing panels our plans include scale spacing of ribs for those who desire to duplicate this appearance via strips of fish line on the balsa covering. An alternate method of construction is to actually install the scale number of ribs and cover the outer panels with silk. If you do so reduce the ribs to 1/16' thick firm balsa. Slip ribs into notches in spar, cement these well.

Cut plywood landing gear mount to shape, drill holes, and cement into slot in ribs. Bend landing gear struts, make one left and one right. Bind auxiliary strut to main strut with fine wire, then solder well. Hold wire with J-bolts and smear installation with cement. Cut bellcrank mount and bolt hole. Slip mount through three center ribs, apply plenty of cement all around.

Chance Vought F4U-1a Corsair Cut-Away Drawing

Wing underside is covered with 1/8' sheet balsa except for curved portion which is covered later with spanwise strips. Butt join 3' wide sheet balsa to form correct chord width and cut to outline shape. Add 1/8' to leading and trailing edges of wing covering to allow for loss due to camber. After a dry test fit apply plenty of cement to underside of ribs and spar and press lower covering in place. Use straight pins to bold covering to structure until cement is dry. Bevel leading and trailing edges of lower covering to continue contours of rib upper camber.

Bend control rod, slip into bellcrank, bolt bellcrank to hardwood mount previously installed. Solder washer or place a 'keeper' at control rod end to prevent it from slipping out of bellcrank. Add wire lead-out lines to bellcrank long enough to extend beyond wing tip.

Recheck landing gear and bellcrank installations, then cover upper surface of wing with 1/8' sheet balsa. Use plenty of cement and apply adhesive to bevelled portions of lower covering. When covering top of center section take care to pass lead-out lines through holes in covering before sheet balsa cements in place. Rough-cut wingtips and cement to covered wing.

Covering the curved portion of the wing is a special operation but not difficult. First cut a series of both 1/8' wide and 1/4' wide strips from firm-but-not-hard 1/8' sheet balsa. The grain must run parallel with the smaller dimension. These strips which will bend readily due to the grain direction are to plank the curved portion of the wing. They will follow the contour formed by the many ribs in this area. Use the 1/4' wide strips for relatively fiat areas of rib camber, the narrow 1/8' strips for sharper camber curves. Cement all strips to the ribs, existing sheet balsa covering, and to each other. It will be necessary to bevel and taper some pieces in order to obtain a good fit. Use plenty of cement and hold strips in place with straight pins until dry.

When all cement has dried thoroughly sand entire wing with fine then extra-fine sandpaper. Keel and fuselage bulkheads are now cut. Make spaces for wing, stabilizer, and control horn very carefully. A hole for the fuel tank must be provided. Before the keel can be slipped on the wing that portion directly below the wing opening must be cut away temporarily. Cement keel to wing securely and replace keel bottom. Add fuselage bulkheads to keel.

Install the commercial fuel tank firmly. Plastic fuel, filling, and vent lines are added. It is important to make certain that the control rod passes through the bulkhead holes as the bulkheads are cemented in place.

Cut hardwood engine mounts, firmly cement to bulkheads. Cement engine mount locks to underside of the mounts and to the bulkheads. Drill two 1/8' diameter holes through each mount and lock assembly, pour cement in the hole, then drive a 1/8' dowel into each hole. Re-cement entire assembly.

Good check of landing gear details is possible via this photo of an F4U-5N night fighter; note radar housing on starboard wing.

Add oil cooler air inlet scoop in leading edge of wings. Cut into wing leading edge as plans illustrate; cement balsa blocks against opening and along wing bottom. When dry, trim carefully with single-edge razor blade to shape shown in front view and the special wing section.

Cut tail surfaces and sand to streamline section. Cement elevator halves to hardwood joiner, add control horn to this assembly. Hinge elevator assembly to stabilizer, cement stabilizer into keel slot. Attach control rod to horn, solder washer to wire end to prevent it from slipping out of hole in horn. Check controls, then cover fuselage after tailwheel strut is installed.

Plank entire fuselage with 1/8' x 1/4' balsa strips beveled and tapered as required for a good fit. Cement strips to bulkheads as well as to each other. When planking is complete press Plastic Balsa into any cracks between strips. Carve tail block, cement in place. Carve cowl from balsa blocks with a sharp knife such as an X-Acto No. 26 blade. To reduce cowl block cost cement four smaller blocks together along horizontal and vertical center lines. When dry trace top view and saw or carve to shape. Repeat with side view, then carve roughly to shape. Rough-hollow to clear engine mounts and cement cowl block to plywood bulkhead.

Finish carving cowl and sandpaper entire model thoroughly. Carefully remove cowl and complete hollowing to the line shown. Sand interior and cut holes for engine cylinder and needle valve. Apply several coats of Sanding Sealer and Butyrate Dope to protect wood from fuel. Drill mounting holes in engine mounts, insert bolts with commercial blind nuts or keepers. Treat bulkhead and engine mounts with sealer and dope to protect the wood, then replace cowl using plenty of cement. Add fin and rudder to fuselage, offset fin as shown.

Sandpaper completed model with very fine paper, then apply four consecutive coats of Butyrate Sanding Sealer brushed on quite liberally. When dry it is sanded with very fine sandpaper. Repeat applications of sealer, after each coat is thoroughly dry sand with rough Flex-I-Grit abrasive coated Mylar. After the tenth coat use the fine Flex-I-Grit wet. It may take fifteen or twenty coats of Butyrate Sanding Sealer to attain the proper degree of smoothness desired. For winning results do not rush the finish.

Install control line lead-out guides in wing tip location shown. These can be made from wire, hardwood, or sheet aluminum but must be fastened securely. Cockpit interior can be outfitted now. It is colored pea green, instrument panel is black. Canopy is from a commercial plastic bubble, windshield is from flat plastic sheet. Do not install these items until a few coats of colored dope have been applied to the model's exterior. Add tin can metal wheel doors.

Although a fine spray gun or air brush is most useful it is not absolutely necessary for the external painting. Ira Kepford's Corsair was colored in three basic shades of blue which blended into each other - hence the advantage of a spray gun. On Corsairs such as Kepford's when flown from land bases entire underside of craft was very light sky blue with a slight tint of green. (If you wish to finish off yours as they appeared when flying off carriers make preceding sentence read: Most of the underside of the craft was very light sky blue with a slight tint of green; this color was applied to horizontal tail bottom, fuselage belly and inboard angled wing center section bottom; bottom of wing outer panels were colored medium blue - like fuselage sides and fin - from fold-line out to tips, on the model this extends from wing rib F to tips. Idea was to make aircraft less visible when resting on carrier decks with wings folded.)

Fuselage sides, fin and rudder on Kepford's Corsair were medium blue while top of fuselage, elevator, stabilizer, and wing were dark insignia blue. The medium blue of the fuselage sides blends into the upper dark and lower light for a continuous transition from light to dark. The light colors are always applied first. A model builder who has no spray gun can simulate the hazy color lines by painting all light colors beyond their normal boundary, then applying the darker color over the light. Sand carefully with worn Flex-I-Grit until a hazy color separation line appears. Rub entire model with rubbing compound, especially the color separation areas.

Chance Vought F4U-1a Corsair Plans

Full size working drawings are available from Hobby Helpers as part of Group Plan #1263.

Notice:

The AMA Plans Service offers a full-size version of many of the plans show here at a very reasonable cost. They will scale the plans any size for you. It is always best to buy printed plans because my scanner versions often have distortions that can cause parts to fit poorly. Purchasing plans also help to support the operation of the Academy of Model Aeronautics - the #1 advocate for model aviation throughout the world. If the AMA no longer has this plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for Model Airplane Plans.

'CORSAIR' LIST OF MATERIAL

(All medium balsa unless noted otherwise)

Two pieces 1/4' x 3' x 36' for keel, spar; (1) 3/8' x 3' x 36' soft balsa for tail surfaces, tail block, wing tips; (6) 1/8' x 3' x 36' for bulkheads, ribs, wing covering; (14) 1/8' x 1/4' x 36' for fuselage planking; (1) 1/8' x 6' x 24' plywood for bulkhead, spar joiner, landing gear supports; (1) 2 1/2' x 2 1/2' x 18' for cowl block; (1) 3/8' x 3/4' x 18' hardwood for engine mount, engine mount lock, bellcrank mount; (1) 3/8' x 3/8' x 12' hardwood for elevator joiner; (1) 1/8' dia x 18' music wire for landing gear struts; (1) 1/16' dia x 36' music wire for control rod, tail wheel strut, arresting hook, landing gear auxiliary struts; (1) large tube Ambroid cement; (1) tube Aero Gloss Plastic Balsa; (1) 16-oz Testor's Butyrate Sanding Sealer; (1) 8 ounces Testor's Butyrate white dope; (1) 8-oz Testor's butyrate Insignia Blue dope; (1) 4-oz Testor's butyrate True Blue dope; (1) 4-oz Testor's butyrate Medium Green dope; (1) 2-oz Testor's butyrate Black dope; (1) 4-oz Testor's butyrate Thinner; (1) large Perfect bellcrank; (2) .032' dia x 36' music wire control line lead out lines.

Miscellaneous: Solder; 'J' bolts; straight pins; fine and extra fine sandpaper; Flex-I-Grit rubbing compound; bolts; nuts; Acme or similar fuel tank; large size plastic tubing; red, white, blue, and black Wondur-Cal decal sheets; Wondur-Cal instruments; Wondur-Cal scale detail sheet.

Paint Mixing Instructions. (1) Remove 1/2-oz of White dope from the jar and add 1-oz of True Blue to the remaining White to make the bottom color; add 1/2-oz of Medium Green to give a slight greenish tint to the light blue. (2) Add 1/2-oz of Medium green to the True Blue for the fuselage side color (and outer wing bottom if your model is to be 'dressed' as per the carrier Corsairs). (3) Add 1-oz of Medium Green to the Insignia Blue for the top color. (4) Mix the 1/2 oz of White with an equal amount of Medium Green for the cockpit interior color. (5) Use the Black for the propeller, landing gear struts and wheel cover inner sides.

ACKNOWLEDGEMENT

The Author wishes to express his sincere appreciation to Commander R. L. Butkins and tbe U.S. Navy, to Mr. A. E. Ferko and Mr. Arthur L. Schoeni, and to Chance Vought Corporation for their kind cooperation which made this article possible.

Add wheels, gun ports, pitot tube, aerial and control outlines. Last are ruled easily with a draftsman's ruling pen and thin white dope. Alternate method to stimulate control outlines is to score the wood with a sharp tool or cut a 'Vee' channel in the covering after the first half dozen coats of sealer have been applied.

Cut cowl hatch and touch up paint where needed. Bolt in engine and replace hatch in permanent or removable manner as desired. The decals are Wondur-Cals. Cut insignia from solid color sheets. The Japanese victory flags and miscellaneous lettering are found on Wondur-cal scale detail sheets which are sure to be welcomed by the scale model enthusiast.

Your model should balance where shown before any flights are undertaken. Flying wires forty to seventy feet long and .014' diameter are recommended. Begin with short lengths and gradually increase the length of the wires as you become familiar with your Corsair.

Posted May 19, 2013