SIEMENS SIMATIC STEP7 Professional comprises the following software packages:. STEP 7 Basic software. S7 – Graph. S7 – SCL.

Download Free Software From the Major PLC Makers. Compare PLCs Free. Siemens Software. Step 7 Professional Trial Software: Use With:.

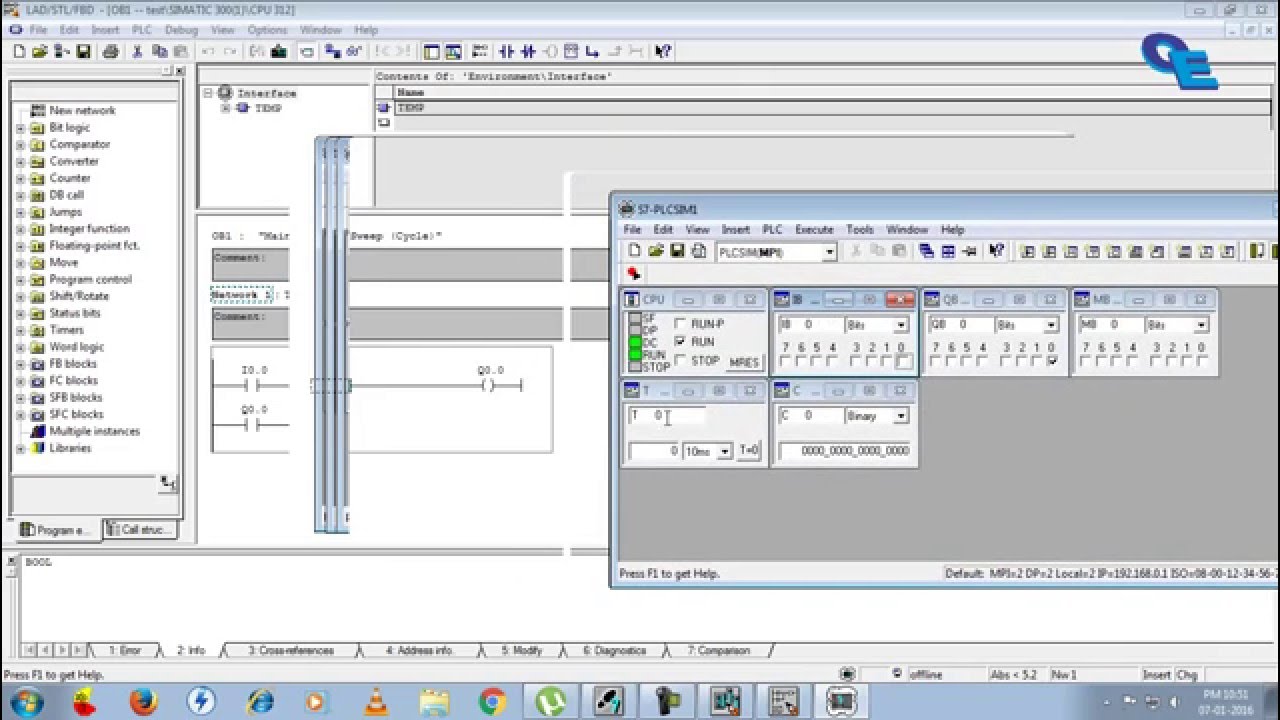

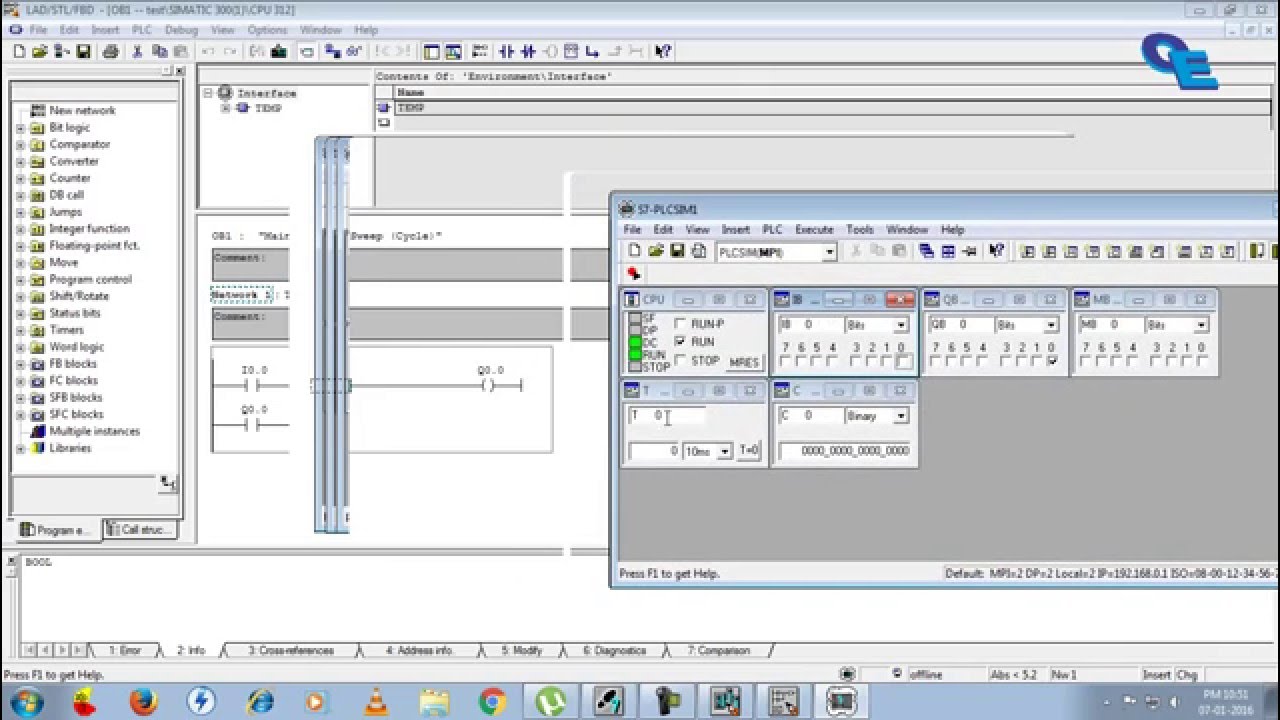

S7 – PLCSIMYou will take advantage of reduced installation efforts and the potential to contribute to a centralized Software Upgrade Plan in addition to a significant price saving in relation to the purchasing of the individual components.SIEMENS SIMATIC STEP7 SoftwareThe standard tool for the SIMATIC S7, SIMATIC C7 and SIMATIC WinAC automation systems is SIEMENS SIMATIC STEP7 software. It helps the user to quickly and efficiently harness the output capabilities of these systems.SIEMENS SIMATIC STEP7 has convenient functions for all automation project phases:. Configuring and parameterizing the hardware.

Specifying communication. Programming. Test, start-up, and service. Documentation, archiving. Operating/diagnostics functionsSIEMENS SIMATIC STEP7 program tools. SIMATIC-Manager:The SIMATIC Manager handles all data pertaining to an automation project, irrespective of the target system (SIMATIC S7, SIMATIC C7 or SIMATIC WinAC) on which it is applied.That entry point for all SIMATIC S7, C7, or WinAC tools is given.

SIMATIC Manager begins automatically the SIMATIC software tools which are required to process the selected data. Symbol-Editor:All global variables (unlike the local formal parameters that are defined when the blocks are programmed) are handled with the tool Symbol Editor. The following functions are available:.

Definition of symbolic designations and comments for process signals (inputs/outputs), flags and blocks. Sorting functions. Data exchange with other Windows programsAll software products have access to the symbol charts created when this tool is used. Thus all devices automatically identify modifications to a symbol parameter.Hardware configuration:The Hardware Configuration tool is used to configure the hardware used for an automation project and to parameterize it. The functions given are as follows:. Automation system configuration: Racks are selected from an online catalog and the modules selected are allocated to the appropriate slots in the racks. Configuring the distributed I / Os is done in the same way as configuring the non-distributed I / Os; it also supports channel-granular I / O modules.

CPU parameter assignment: Menu-driven properties such as reboot features and cycle-time monitoring can be set. Multi-computing improves. In the CPU, the data entered is stored in machine data blocks. Assignment of module parameters: All customizable parameters of the modules can be specified by the user in the input screen types. Settings are becoming unnecessary via DIP switches. Hardware modules parameterization happens automatically during the acceleration of the CPU.

Therefore, a module shift can be rendered without a particular parameterization. Function module (FM) and communications processor (CP) parameter assignment:Such parameterization often happens in the design of the hardware in the same way as the other components are parameterized. Hardware-module-specific screen forms and rules are provided for and FM and CP (included in the bundle of FM / CP functions) for this parameterization. The device avoids incorrect inputs by providing only permissible entry choices on the screen forms for parameter assignments.Communication Configuration. Configuring and display of communication links. Time-driven cyclic data transmission via MPI:– Selection of communication partners– Entering of data source and data destination in a table. Generation of all system datablocks (SDBs) to be loaded and their complete transmission to all CPUs take placeautomatically– Parameterization of the selected communication blocks in the customary programminglanguage (e.g., LAD).

Event-driven data transmission– Definition of communication links.– Selection of the communication function blocks (CFBs) from the integrated block library.– Parameterization of the selected communication blocks in the customary programminglanguage (e.g., LAD).System DiagnosticsSystem diagnostics offer the user an overview of the status of the automation system. The following well-proven programming languages are available:. Ladder (LAD,. Function Block Diagram (FBD). Instruction List (IL)The user should build programs that meet the requirements of DIN EN 6.1131-3. The STEP 7 programming languages have a comprehensive set of instructions, similar to STEP 5. This allows even complex functions to be programmed easily (i.e., without having great programming knowledge) and quickly.

The following functions are provided. Binary logic (incl. Edge evaluation). Word operation.

Timers/counters. Comparison functions. Conversion functions.

(or ','), hot-keys F13 F17, page. Designed to fit the Apple™ wireless keyboard in an elegant way. Lmp wkp 1644 bluetooth keypad 2 for mac download. up/down, arrow up/down, delete forward, enter key.

Shift/rotate. Mathematical functions (incl. Trigonometry, exponents, logarithms). Program control (branches, branch distribution, calls, Master Control Relays).In addition, improved testing and service functions make programming easier:. Setting breakpoints (only S7-400). Forcing of inputs/outputs (only S7-400).

Rewiring. Display of cross-referencesStatus functions:. Download and testing of blocks directly from the editor. Status of several blocks at the same time. Search functions:Specific locations within the program can be found quickly using search criteria (such as symbolic name, operand) (XRef).Supported Operating systems.

- Author: admin

- Category: Category

SIEMENS SIMATIC STEP7 Professional comprises the following software packages:. STEP 7 Basic software. S7 – Graph. S7 – SCL.

Download Free Software From the Major PLC Makers. Compare PLCs Free. Siemens Software. Step 7 Professional Trial Software: Use With:.

S7 – PLCSIMYou will take advantage of reduced installation efforts and the potential to contribute to a centralized Software Upgrade Plan in addition to a significant price saving in relation to the purchasing of the individual components.SIEMENS SIMATIC STEP7 SoftwareThe standard tool for the SIMATIC S7, SIMATIC C7 and SIMATIC WinAC automation systems is SIEMENS SIMATIC STEP7 software. It helps the user to quickly and efficiently harness the output capabilities of these systems.SIEMENS SIMATIC STEP7 has convenient functions for all automation project phases:. Configuring and parameterizing the hardware.

Specifying communication. Programming. Test, start-up, and service. Documentation, archiving. Operating/diagnostics functionsSIEMENS SIMATIC STEP7 program tools. SIMATIC-Manager:The SIMATIC Manager handles all data pertaining to an automation project, irrespective of the target system (SIMATIC S7, SIMATIC C7 or SIMATIC WinAC) on which it is applied.That entry point for all SIMATIC S7, C7, or WinAC tools is given.

SIMATIC Manager begins automatically the SIMATIC software tools which are required to process the selected data. Symbol-Editor:All global variables (unlike the local formal parameters that are defined when the blocks are programmed) are handled with the tool Symbol Editor. The following functions are available:.

Definition of symbolic designations and comments for process signals (inputs/outputs), flags and blocks. Sorting functions. Data exchange with other Windows programsAll software products have access to the symbol charts created when this tool is used. Thus all devices automatically identify modifications to a symbol parameter.Hardware configuration:The Hardware Configuration tool is used to configure the hardware used for an automation project and to parameterize it. The functions given are as follows:. Automation system configuration: Racks are selected from an online catalog and the modules selected are allocated to the appropriate slots in the racks. Configuring the distributed I / Os is done in the same way as configuring the non-distributed I / Os; it also supports channel-granular I / O modules.

CPU parameter assignment: Menu-driven properties such as reboot features and cycle-time monitoring can be set. Multi-computing improves. In the CPU, the data entered is stored in machine data blocks. Assignment of module parameters: All customizable parameters of the modules can be specified by the user in the input screen types. Settings are becoming unnecessary via DIP switches. Hardware modules parameterization happens automatically during the acceleration of the CPU.

Therefore, a module shift can be rendered without a particular parameterization. Function module (FM) and communications processor (CP) parameter assignment:Such parameterization often happens in the design of the hardware in the same way as the other components are parameterized. Hardware-module-specific screen forms and rules are provided for and FM and CP (included in the bundle of FM / CP functions) for this parameterization. The device avoids incorrect inputs by providing only permissible entry choices on the screen forms for parameter assignments.Communication Configuration. Configuring and display of communication links. Time-driven cyclic data transmission via MPI:– Selection of communication partners– Entering of data source and data destination in a table. Generation of all system datablocks (SDBs) to be loaded and their complete transmission to all CPUs take placeautomatically– Parameterization of the selected communication blocks in the customary programminglanguage (e.g., LAD).

Event-driven data transmission– Definition of communication links.– Selection of the communication function blocks (CFBs) from the integrated block library.– Parameterization of the selected communication blocks in the customary programminglanguage (e.g., LAD).System DiagnosticsSystem diagnostics offer the user an overview of the status of the automation system. The following well-proven programming languages are available:. Ladder (LAD,. Function Block Diagram (FBD). Instruction List (IL)The user should build programs that meet the requirements of DIN EN 6.1131-3. The STEP 7 programming languages have a comprehensive set of instructions, similar to STEP 5. This allows even complex functions to be programmed easily (i.e., without having great programming knowledge) and quickly.

The following functions are provided. Binary logic (incl. Edge evaluation). Word operation.

Timers/counters. Comparison functions. Conversion functions.

(or ','), hot-keys F13 F17, page. Designed to fit the Apple™ wireless keyboard in an elegant way. Lmp wkp 1644 bluetooth keypad 2 for mac download. up/down, arrow up/down, delete forward, enter key.

Shift/rotate. Mathematical functions (incl. Trigonometry, exponents, logarithms). Program control (branches, branch distribution, calls, Master Control Relays).In addition, improved testing and service functions make programming easier:. Setting breakpoints (only S7-400). Forcing of inputs/outputs (only S7-400).

Rewiring. Display of cross-referencesStatus functions:. Download and testing of blocks directly from the editor. Status of several blocks at the same time. Search functions:Specific locations within the program can be found quickly using search criteria (such as symbolic name, operand) (XRef).Supported Operating systems.